The Le Grand Paris project aims to unite the French capital with multiple suburban communities.

Western Europe’s largest infrastructure project will double the length of the Parisian métro network by 2030 and connect the city center to the suburbs.

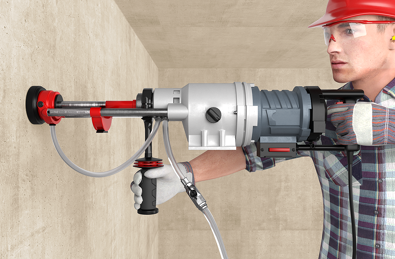

In 14 years, 200km of additional rail lines with 68 new metro stations will be built. The FIS EM Plus was used to connect the floor slabs to the retaining walls by providing stability and durability to the project. To meet this demanding requirements, an additional ETA for the service life of 100 years was specially granted.

In a short interview, Dr. Thilo Pregartner, Head of Technology Transfer & Approvals, provides helpful expertise on our FIS EM Plus epoxy resin mortar. For what applications does an injection mortar need a service life of 100 years and why does the FIS EM Plus even have 120 years? Which additional product features are particularly helpful for the installer? The answers to all these questions can be found in the expert interview.

The fischer injection systems are not only developed in Germany, but also manufactured in Germany. From the development of the formulation in the in-house laboratory to the mixing of the ingredients and the injection of the specially developed cartridges, everything is manufactured in one plant in the south of Germany.

The close coordination of the individual teams ensures continuous quality control and perfectly coordinated production processes. The many fischer subsidiaries enable us to react to customer needs and changing market conditions at short notice. In addition to the external ETA and ICC tests, the products are also tested in our own test laboratory after each production step, e.g. by means of pull-out tests. Thus the fischer injection systems meet the highest quality requirements